Mass Transfer Columns

Multi-Stage Process Blocks

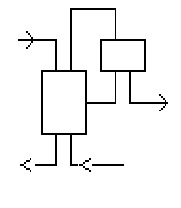

This section contains detailed specification requirements for multi-stage process blocks available in ESP. Generally, these process units are columns/towers. The process units available are:

- Stripper

- Absorber

- Extractor

The unit to be specified is selected from the display using the Arrow Keys and then the Enter Key.

Additional column specification facilities are available via the Action Key and then by selecting the Parameters and Config facilities. These facilities are detailed for each individual unit.

Distillation/Stripper Unit

This is a multi-stage conventional or environmental unit allowing species in a liquid to be separated either by distillation, or by the action of a countercurrent vapor stream (i.e., stripper). The unit can hold a maximum of 50 stages, 10 feed streams, and 10 exit streams.

When this block is selected the user can choose either an electrolyte column or a non-electrolyte column (if a non-electrolyte model was created). In the case of an electrolyte column, an aqueous phase must be present in every liquid stream. The liquid feed and/or liquid product can contain both an aqueous and nonaqueous liquid phase, and just an aqueous phase alone. In the case of a non-electrolyte column, only the non-electrolyte liquid phase exists (electrolyte chemistry is not considered).

When this block is selected the user is forced to choose either a standard column or a mass transfer limited column. The standard column applies for the rigorous equilibrium model which is based on the component material balance, energy balance and thermodynamic correlations and criteria of phase equilibria at each stage; however, the mass transfer limited column applies for the nonequilibrium model, which explicitly accounts for mass and heat transfer except material and energy balance and phase equilibria. Therefore, the mass transfer limited column may provide more realistic concentration and temperature profile through the column. In the mass transfer limited column, each stage is divided into five parts: vapor bulk, vapor film, vapor/liquid interface, liquid film and liquid bulk; the mass-transfer and heat-transfer resistances are assumed to lie in two thin film layers that are separated by the vapor/liquid interface; at the interface, the vapor and the liquid are in equilibrium.

The unit may be set to a single stage standard or mass transfer limited column without condenser and reboilor.

Data Requirements

A minimum of one feed stream and two exit streams (i.e., distillate and bottoms) must be named when using the unit for distillation. An additional feed must be added when using the unit as a stripper. The feed stream temperature, pressure, flow and composition data must be specified by the user or be a product stream from another Process Block. The number of stages will default to 10 and appear that way on the initial screen. The user may override this value. If there is a condenser or reboiler, these will count as stages. Additionally, various column operating parameter information must be supplied by the user.