Mass Transfer Towers

Contents

Mass Transfer Towers Overview

To select a mass transfer tower as a model, you select multistage blocks and then select absorber or stripper. The program will then ask if you want a mass transfer tower.

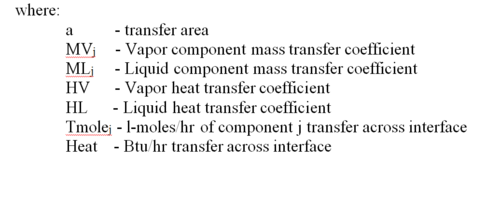

The mass and heat transfer coefficients along with the interfacial area are entered via the parameters option on the action bar. At least one value should be entered for the vapor and liquid overall mass transfer coefficient. Values for stages not entered are interpolated. If component mass transfer coefficients are desired, answer yes when the option is displayed. The values entered for component mass transfer will override the overall values entered, any component not specified will have the value entered for the overall coefficient.

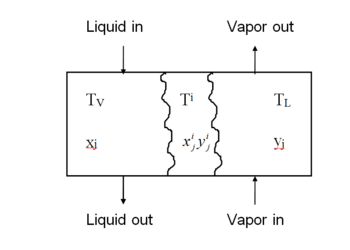

The larger the mass and heat transfer coefficient, the closer the tower will be to equilibrium conditions. For a gas-liquid tower the major resistance is normally on the mass transfer coefficient on the vapor side of the interface. In such a case the liquid side coefficient is set large and the vapor side coefficient adjusted to match experimental results. The heat transfer coefficients are normally set large.

Column Stage

Some Frequently Asked Questions about OLI's Mass Transfer Columns

What are the default input data currently used with each tray type?

Sieve Tray

There are four input parameters for the Sieve Tray Sieve Tray: Four input parameters

1. Column diameter (coldia): If not entered, ESP calculates diameter using <ref>Perry’s Chemical Engineer’s handbook, 6th Edition, pages 18-6</ref>

su = 0.65d0/dsqrt(denv*0.062428d0) calcdiam = dsqrt(av*4.0d0/(pi*su))

where, su = Superficial gas velocity, m/sec denv = Vapor density, kg/m3 av = Vapor flow rate, m3/sec 0.65 = Gas phase kintetic-energy term (F factor), uniteless calcdiam = calculated diameter, m Please note, unit conversions are not shown in the equations.

Reference 1: Perry’s Chemical Engineer’s handbook, 6th Edition, pages 18-6.

2. Weir height (hweir): If not entered, hweir = 1.0 inch.

3. Clear liquid height (hl): If not entered, ESP calculates the clear liquid height or the height of crest over wire (hl) using Reference 2.

hl = 664.d0*(al/lw)**(0.667)*1.0d-3

where al = Liquid flow rate, m3/sec lw = Weir length, m hl = Clear liquid height, m

The weir length (lw) is calculated from a correlation using Reference 2.

lw = exp(log(al/6.309d-5)/25)/2.5d0 * 0.3048d0

Reference 2: Perry’s Chemical Engineer’s handbook, 6th Edition, pages 18-10,11.

4. Froth height (hf): If not entered, hf = 2.0*hl. For sieve tray, the weir length information is accounted in our model. Weir height is the only parameter set as default unless it is a user input. Hole diameter and/or arrangements are not required in the currently implemented model, however, current model uses above information plus diffusivity, Schimdt number, porosity of froth and other readily available data to calculate interfacial area per unit froth volume and finally mass transfer coefficients in the gas and liquid phase. More details about OLI’s Sieve tray can be found in Reference 3. Reference 3: Moniuk, W., Bekassy-Molnar, E., Mustafa, H. and Pohorecki, R., “Absorption of carbon dioxide into sodium hydroxide solutions in a sieve plate column”, Hungarian Journal of Industrial Chemistry, 17 (1989), 93-105.

Perry’s Chemical Engineer’s handbook, 6th Edition, pages 18-6